MultiViz AI: Revolutionizing Industrial Monitoring with AI-Based Vibration Remote Monitoring

Maximize the potential profitability of your monitoring of industrial assets with MultiViz AI Vibration Analyst. This all-in-one, cloud-based AI assistant seamlessly integrates AI, IoT, and analytics to enhance performance, prolong asset lifecycles, and minimize operational downtime and costs.

MultiViz AI is tailored for specialist engineers:

- Vibration Analyst

- Maintenance Planner

- Condition Monitoring Engineer

Limited Free License for Vibration Assistant AI

– Offer Expires May 2024!

Maintenance Company Revenue Gain Calculator

COMPANY REVENUE

Enable to assess your hidden potential revenue with MultiViz AI assistant

Why MultiViz AI?

Transform Your Tomorrow: All You Need is the Shift from A to B

Assume example use case for a CNC machine floor assuming operations for 30 hours per week.

What is MultiViz AI?

MultiViz serves as a Vibration AI assistant system, possessing capabilities comparable to those of a seasoned vibration analyst.

It efficiently monitors a thousand machines at a reduced cost while achieving higher levels of accuracy.

- Expert Attention Identification:

- Capable of identifying machines that require human expert attention, streamlining the focus on critical areas.

- Fault Indication Precision:

- Highlights significant measurements that suggest potential faults, aiding in proactive maintenance and issue prevention.

- Data Quality Assessment:

- Conducts checks on data quality and sensor mounting quality, ensuring accurate and reliable insights.

- Comprehensive Issue Detection:

- Can detect 100% of machine issues, providing a thorough analysis to enhance operational efficiency and minimize downtime.

- Low False Alarm Rate:

- Maintains a false alarm rate of less than 3%, a significant improvement compared to competitors’ rates ranging from 20-50%, ensuring precise and reliable alerts.

Don’t Miss Out!

Free Trial and Huge Discount

Exclusive MultiViz Premium License

Act Now Before May 2024 Expires!

How It works?

Contact Us: Reach out to us to begin the process.

Assigned Account Manager: Once connected, we’ll assign a dedicated account manager to assist you in onboarding your data.

Quality Reports Delivery: Expect to receive detailed quality reports, showcasing an average reduction of unplanned downtime by 43% and a 28% improvement in maintenance productivity.

-

1: Collect Data

Data is collected from any type of sensors and transmitted to our gateway in cloud.

-

2: Store and Manage Data

The information is securely stored in the cloud Asset management.

-

3: AI Analyse and Inspect

Viking Analytics AI and vibration experts analyze the data.

-

4: Predict and Recommendation

You will receive reports on prioritized machines and diagnostic opinions every 2 weeks with recommendations and machines to be prioritised.

Empower Vibration Analysts to Monitor

Factories with Our Advanced AI Technology.

Voices of Delight; What Our Customers Are Saying

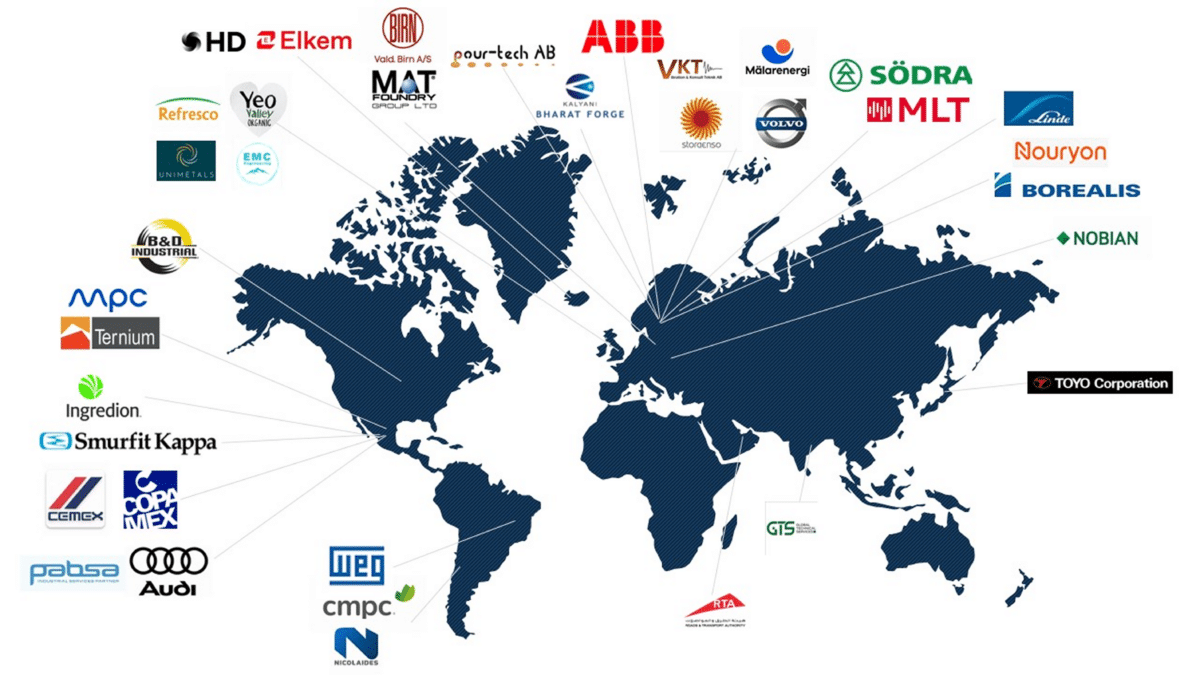

Who are we?

Viking Analytics – Driving AI Innovation in Europe, Acknowledged by AI Sweden

Frequently Asked Questions

MultiViz is an advanced monitoring system functioning as an experienced vibration analyst, capable of simultaneously monitoring tens of thousands of machines and providing initial diagnostic insights. With a remarkable early detection rate of over 95% and less than 3% false alarms, MultiViz ensures exceptional fault detection accuracy without the need for specific threshold settings or manual inputs such as machine plate information or running speeds.

Supporting a diverse range of machine types across industries, MultiViz accommodates various sensor data and brands. We offer comprehensive support, including technical assistance for seamlessly connecting all your machines and sensors to MultiViz. Our support includes documentation, tutorials, and potential training sessions to assist in navigation, data connectivity setup, and optimizing data source connections and analysis during the trial.

The MultiViz primarily supports various vibration sensor brands and types for machine monitoring. It’s adaptable to different sensor models, offering comprehensive machine health insights. Guidance for sensor selection, installation, and setup is available upon request.

Robust encryption and industry-standard security measures safeguard connected data. Customers data shared remains confidential and is deleted after the trial ends, in accordance with the privacy policy.